A traffic collision avoidance system or traffic alert and collision avoidance system (both abbreviated as TCAS) is an aircraft collision avoidance system designed to reduce the incidence of mid-air collisions between aircraft. It monitors the airspace around an aircraft for other aircraft equipped with a corresponding active transponder, independent of air traffic control, and warns pilots of the presence of other transponder-equipped aircraft which may present a threat of mid-air collision (MAC). It is a type of airborne collision avoidance system mandated by the International Civil Aviation Organization to be fitted to all aircraft with a maximum take-off mass (MTOM) of over 5700 kg (12,586 lbs) or authorized to carry more than 19 passengers.

Official definition from PANS-ATM (Nov 2007): ACAS / TCAS is an aircraft system based on secondary surveillance radar (SSR) transponder signals, which operates independently of ground-based equipment to provide advice to the pilot on potential conflicting aircraft that are equipped with SSR transponders.

In modern glass cockpit aircraft, the TCAS display may be integrated in the Navigation Display (ND) or Electronic Horizontal Situation Indicator (EHSI); in older glass cockpit aircraft and those with mechanical instrumentation, such an integrated TCAS display may replace the mechanical Vertical Speed Indicator (which indicates the rate with which the aircraft is descending or climbing).

The TCAS system builds a three dimensional map of aircraft in the airspace, incorporating their range (garnered from the interrogation and response round trip time), altitude (as reported by the interrogated aircraft), and bearing (by the directional antenna from the response). Then, by extrapolating current range and altitude difference to anticipated future values, it determines if a potential collision threat exists.

TCAS and its variants are only able to interact with aircraft that have a correctly operating mode C or mode S transponder. A unique 24-bit identifier is assigned to each aircraft that has a mode S transponder.

The next step beyond identifying potential collisions is automatically negotiating a mutual avoidance maneuver (currently, maneuvers are restricted to changes in altitude and modification of climb/sink rates) between the two (or more) conflicting aircraft. These avoidance maneuvers are communicated to the flight crew by a cockpit display and by synthesized voice instructions.

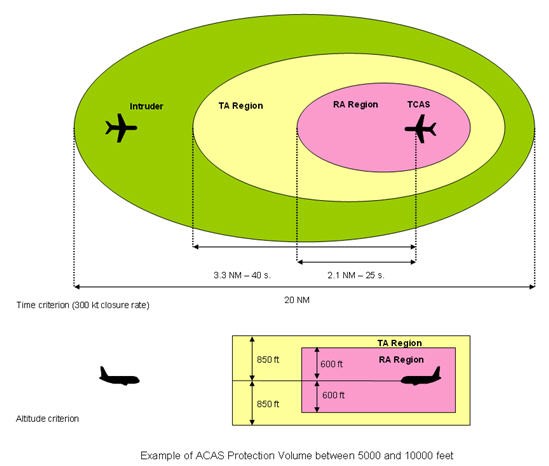

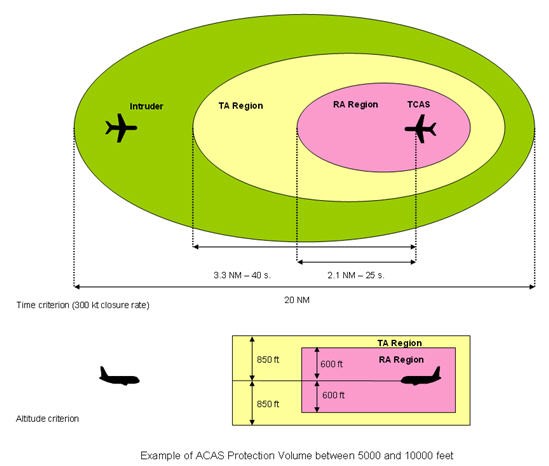

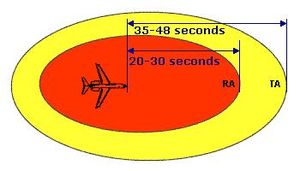

A protected volume of airspace surrounds each TCAS equipped aircraft. The size of the protected volume depends on the altitude, speed, and heading of the aircraft involved in the encounter. The illustration below gives an example of a typical TCAS protection volume.

TCAS II issues the following types of aural annunciations:

When an RA is issued, pilots are expected to respond immediately to the RA unless doing so would jeopardize the safe operation of the flight. This means that aircraft will at times have to manoeuver contrary to ATC instructions or disregard ATC instructions. In these cases, the controller is no longer responsible for separation of the aircraft involved in the RA until the conflict is terminated.

On the other hand, ATC can potentially interfere with the pilot’s response to RAs. If a conflicting ATC instruction coincides with an RA, the pilot may assume that ATC is fully aware of the situation and is providing the better resolution. But in reality ATC is not aware of the RA until the RA is reported by the pilot. Once the RA is reported by the pilot, ATC is required not to attempt to modify the flight path of the aircraft involved in the encounter. Hence, the pilot is expected to “follow the RA” but in practice this does not yet always happen.

Some States have implemented “RA downlink” which provides air traffic controllers with information about RAs posted in the cockpit obtained via Mode S radars. Currently, there are no ICAO provisions concerning the use of RA downlink by air traffic controllers.

The following points receive emphasis during pilot training:

However, it is well understood that part of the remaining risk is that TCAS may induce midair collisions: "In particular, it is dependent on the accuracy of the threat aircraft’s reported altitude and on the expectation that the threat aircraft will not make an abrupt maneuver that defeats the TCAS Resolution Advisory (RA). The safety study also shows that TCAS II will induce some critical near midair collisions..." (See page 7 of Introduction to TCAS II Version 7 and 7.1 (PDF) in external links below).

One potential problem with TCAS II is the possibility that a recommended avoidance maneuver might direct the flight crew to descend toward terrain below a safe altitude. Recent requirements for incorporation of ground proximity mitigate this risk. Ground proximity warning alerts have priority in the cockpit over TCAS alerts.

Some pilots have been unsure how to act when their aircraft was requested to climb whilst flying at their maximum altitude. The accepted procedure is to follow the climb RA as best as possible, temporarily trading speed for height. The climb RA should quickly finish. In the event of a stall warning, the stall warning would take priority.

Both cases have been already addressed by Version 7.0 of TCAS II and are currently handled by a corrective RA together with a visual indication of a green arc in the IVSI display to indicate the safe range for the climb or descent rate. However, it has been found that in some cases these indications could lead to a dangerous situation for the involved aircraft. For example, if a TCAS event occurs when two aircraft are descending one over the other for landing, the aircraft at the lower altitude will first receive a "Descend, descend" RA, and when reaching an extreme low altitude, this will change to a "Adjust Vertical Speed, Adjust" RA, together with a green arc indication directing the pilot to level off the aircraft. This could place the aircraft dangerously into the path of the intruder above, who is descending to land. A change proposal has been issued to correct this problem.

TCAS equipment which is capable of processing ADS-B messages may use this information to enhance the performance of TCAS, using techniques known as "hybrid surveillance". As currently implemented, hybrid surveillance uses reception of ADS-B messages from an aircraft to reduce the rate at which the TCAS equipment interrogates that aircraft. This reduction in interrogations reduces the use of the 1030/1090 MHz radio channel, and will over time extend the operationally useful life of TCAS technology. The ADS-B messages will also allow low cost (for aircraft) technology to provide real time traffic in the cockpit for small aircraft. Currently UAT based traffic uplinks are provided in Alaska and in regions of the East coast of the USA.

Hybrid surveillance does not include the use any of the aircraft flight information in the TCAS conflict detection algorithms; ADS-B is used only to identify aircraft that can safely be interrogated at a lower rate.

In the future, prediction capabilities may be improved by using the state vector information present in ADS-B messages. Also, since ADS-B messages can be received at greater range than TCAS normally operates, aircraft can be acquired earlier by the TCAS tracking algorithms.

The identity information present in ADS-B messages can be used to label other aircraft on the cockpit display (where present), painting a picture similar to what an air traffic controller would see and improving situational awareness.

TCAS II is the second and current generation of instrument warning TCAS, used in the majority of commercial aviation aircraft (see table below). It offers all the benefits of TCAS I, but will also offer the pilot direct, vocalized instructions to avoid danger, known as a "Resolution Advisory" (RA). The suggestive action may be "corrective", suggesting the pilot change vertical speed by announcing, "Descend, descend", "Climb, climb" or "Adjust Vertical Speed Adjust" (meaning reduce vertical speed). By contrast a "preventive" RA may be issued which simply warns the pilots not to deviate from their present vertical speed, announcing, "Monitor vertical speed" or "Maintain vertical speed, Maintain". TCAS II systems coordinate their resolution advisories before issuing commands to the pilots, so that if one aircraft is instructed to descend, the other will typically be told to climb — maximising the separation between the two aircraft.

As of 2006, the only implementation that meets the ACAS II standards set by ICAO was Version 7.0 of TCAS II, produced by three avionics manufacturers: Rockwell Collins, Honeywell, and ACSS (Aviation Communication & Surveillance Systems; an L-3 Communications and Thales Avionics company).

After the Überlingen mid-air collision (July 1, 2002), studies have been made to improve TCAS II capabilities. Following extensive Eurocontrol input and pressure, a revised TCAS II Minimum Operational Performance Standards (MOPS) document has been jointly developed by RTCA (Special Committee SC-147) and EUROCAE. As a result, by 2008 the standards for Version 7.1 of TCAS II have been issued and published as RTCA DO-185B (June 2008) and EUROCAE ED-143 (September 2008).

TCAS II Version 7.1 will be able to issue RA reversals in coordinated encounters, in case one of the aircraft doesn't follow the original RA instructions (Change proposal CP112E). Other changes in this version are the replacement of the ambiguous "Adjust Vertical Speed, Adjust" RA with the "Level off, Level off" RA, to prevent improper response by the pilots (Change proposal CP115).; and the improved handling of corrective/preventive annunciation and removal of green arc display when a positive RA weakens solely due to an extreme low or high altitude condition (1000 feet AGL or below, or near the aircraft top ceiling) to prevent incorrect and possibly dangerous guidance to the pilot (Change proposal CP116).

Studies conducted for Eurocontrol, using recently recorded operational data, indicate that currently the probability of a mid-air collision in European airspace is 2.7 x 10−8 which equates to one in every 3 years. When TCAS II Version 7.1 is implemented, that probability will be reduced by a factor of 4.

TCAS III attempts to use the TCAS directional antenna to assign a bearing to other aircraft, and thus be able to generate a horizontal maneuver (e.g. turn left or right). However, it was judged by the industry to be unfeasible due to limitations in the accuracy of the TCAS directional antennas. The directional antennas were judged not to be accurate enough to generate an accurate horizontal-plane position, and thus an accurate horizontal resolution. By 1995, years of testing and analysis determined that the concept was unworkable using available surveillance technology (due to the inadequacy of horizontal position information), and that horizontal RAs were unlikely to be invoked in most encounter geometries. Hence, all work on TCAS III was suspended and there are no plans for its implementation. The concept has later evolved and been replaced by TCAS IV.

TCAS IV has replaced the TCAS III concept by the mid 1990s. One of the results of TCAS III experience has been that the directional antenna used by the TCAS processor to assign a bearing to a received transponder reply is not accurate enough to generate an accurate horizontal position, and thus a safe horizontal resolution. TCAS IV uses additional position information encoded on an air-to-air data link to generate the bearing information, so the accuracy of the directional antenna would not be a factor.

TCAS IV development continued for some years, but the appearance of new trends in data link such as Automatic Dependent Surveillance - Broadcast (ADS-B) have pointed out a need to re-evaluate whether a data link system dedicated to collision avoidance such as TCAS IV should be incorporated into a more generic system of air-to-air data link for additional applications. As a result of these issues, the TCAS IV concept was abandoned as ADS-B development started.

This accident could have been prevented if TCAS was able to reverse the original RA for one of the aircraft when it detects that the crew of the other one is not following their original TCAS RA, but conflicting ATC instructions instead. This is one of the features that will be implemented within Version 7.1 of TCAS II.

Implementation of TCAS II Version 7.1 has been originally planned to start between 2009 and 2011 by retrofitting and forward fitting all the TCAS II equipped aircraft, with the goal that by 2014 the version 7.0 will be completely phased out and replaced by version 7.1. The FAA and EASA have already published the TCAS II Version 7.1 Technical Standard Order (TSO-C119c and ETSO-C119c, respectively) effective since 2009, based on the RTCA DO-185B and EUROCAE ED-143 standards. On 25 September 2009 FAA issued Advisory Circular AC 20-151A providing guidance for obtaining airworthiness approval for TCAS II systems, including the new version 7.1. On 5 October 2009 the Association of European Airlines (AEA) published a Position Paper showing the need to mandate TCAS II Version 7.1 on all aircraft as a matter of priority. On 25 March 2010 the European Aviation Safety Agency (EASA) published Notice of Proposed Amendment (NPA) No. 2010-03 pertaining to the introduction of ACAS II software version 7.1. On 14 September 2010 EASA published the Comment Response Document (CRD) to the above mentioned NPA. Separately, a proposal has been made to amend the ICAO standard to require TCAS II Version 7.1 for compliance with ACAS II SARPs.

ICAO has circulated an amendment for formal member state agreement which recommends TCAS II Change 7.1 adoption by 1 January 2014 for forward fit and 1 January 2017 for retrofit. Following the feedback and comments from airline operators, EASA has proposed the following dates for the TCAS II Version 7.1 mandate in European airspace: forward fit (for new aircraft) 1 March 2012, retrofit (for existing aircraft) 1 December 2015. These dates are proposed dates, subject to further regulatory processes, and are not final until the Implementing Rule has been published.

Among the system manufacturers, by February 2010 ACSS certified Change 7.1 for their TCAS 2000 and Legacy TCAS II systems, and is currently offering Change 7.1 upgrade for their customers. By June 2010 Honeywell published a white paper with their proposed solutions for TCAS II Version 7.1. Rockwell Collins currently announces that their TCAS-94, TCAS-4000 and TSS-4100 TCAS II compliant systems are software upgradeable to Change 7.1 when available.

While the safety benefits of current TCAS implementations are self-evident, the full technical and operational potential of TCAS is not fully exploited due to limitations in current implementations (most of which will need to be addressed in order to further facilitate the design and implementation of Free flight):

Official definition from PANS-ATM (Nov 2007): ACAS / TCAS is an aircraft system based on secondary surveillance radar (SSR) transponder signals, which operates independently of ground-based equipment to provide advice to the pilot on potential conflicting aircraft that are equipped with SSR transponders.

|

| TCAS and EHSI cockpit display |

Impetus for a collision prevention system

Research into collision avoidance systems has been ongoing since at least the 1950s. ICAO and aviation authorities such as the Federal Aviation Administration were spurred into action after several major mid-air collisions involving great loss of life. Some of these mid-air accidents include:- Grand Canyon midair collision in 1956;

- The New York air disaster in 1960;

- The Asheville midair collision in 1967;

- The Zagreb mid-air collision in 1976;

- PSA Flight 182, a Boeing 727 which collided with a Cessna 172 in 1978;

- The Ukraine Aeroflot mid-air collision, between two Tupolev Tu-134 in 1979;

- Aeroméxico Flight 498, a 1986 collision similar to PSA Flight 182, which finally spurred the US Congress and other regulatory bodies into action and led to mandatory collision avoidance equipment.

- Chakri Dadri midair collision over a town near New Delhi, India in 1996;

- The Japan Airlines near-miss incident in 2001;

- The Überlingen mid-air collision, between a Boeing 757 and a Tupolev Tu-154 in 2002, where the Tupolev pilots declined to follow their TCAS resolution advisory (RA), instead following the directions of the air traffic controller, while the Boeing pilots followed their TCAS RA. having no ATC instruction. By the time the crews of the two planes actually saw each other, it was too late and the planes collided, killing 71;

- The Gol Flight 1907 collision with an Embraer Legacy 600 in 2006;

TCAS basics

System description

TCAS involves communication between all aircraft equipped with an appropriate transponder (provided the transponder is enabled and set up properly). Each TCAS-equipped aircraft interrogates all other aircraft in a determined range about their position (via the 1,030 MHz radio frequency), and all other craft reply to other interrogations (via 1,090 MHz). This interrogation-and-response cycle may occur several times per second.The TCAS system builds a three dimensional map of aircraft in the airspace, incorporating their range (garnered from the interrogation and response round trip time), altitude (as reported by the interrogated aircraft), and bearing (by the directional antenna from the response). Then, by extrapolating current range and altitude difference to anticipated future values, it determines if a potential collision threat exists.

TCAS and its variants are only able to interact with aircraft that have a correctly operating mode C or mode S transponder. A unique 24-bit identifier is assigned to each aircraft that has a mode S transponder.

The next step beyond identifying potential collisions is automatically negotiating a mutual avoidance maneuver (currently, maneuvers are restricted to changes in altitude and modification of climb/sink rates) between the two (or more) conflicting aircraft. These avoidance maneuvers are communicated to the flight crew by a cockpit display and by synthesized voice instructions.

A protected volume of airspace surrounds each TCAS equipped aircraft. The size of the protected volume depends on the altitude, speed, and heading of the aircraft involved in the encounter. The illustration below gives an example of a typical TCAS protection volume.

System components

A TCAS installation consists of the following components:- TCAS computer unit

- Performs airspace surveillance, intruder tracking, its own aircraft altitude tracking, threat detection, RA maneuver determination and selection, and generation of advisories. The TCAS Processor uses pressure altitude, radar altitude, and discrete aircraft status inputs from its own aircraft to control the collision avoidance logic parameters that determine the protection volume around the TCAS aircraft.

- Antennas

- The antennas used by TCAS II include a directional antenna that is mounted on the top of the aircraft and either an omnidirectional or a directional antenna mounted on the bottom of the aircraft. Most installations use the optional directional antenna on the bottom of the aircraft. In addition to the two TCAS antennas, two antennas are also required for the Mode S transponder. One antenna is mounted on the top of the aircraft while the other is mounted on the bottom. These antennas enable the Mode S transponder to receive interrogations at 1030 MHz and reply to the received interrogations at 1090 MHz.

- Cockpit presentation

- The TCAS interface with the pilots is provided by two displays: the traffic display and the RA display. These two displays can be implemented in a number of ways, including displays that incorporate both displays into a single, physical unit. Regardless of the implementation, the information displayed is identical. The standards for both the traffic display and the RA display are defined in DO-185A.

TCAS operation

The following section describes the TCAS operation based on TCAS II, since this is the version that has been adopted as an international standard (ACAS II) by ICAO and aviation authorities worldwide.TCAS operation modes

TCAS II can be currently operated in the following modes:- Stand-by

- Power is applied to the TCAS Processor and the mode S transponder, but TCAS does not issue any interrogations and the transponder will reply to only discrete interrogations.

- Transponder

- The mode S transponder is fully operational and will reply to all appropriate ground and TCAS interrogations. TCAS remains in stand-by.

- Traffic advisories only

- The mode S transponder is fully operational. TCAS will operate normally and issue the appropriate interrogations and perform all tracking functions. However, TCAS will only issue traffic advisories (TA), and the resolution advisories (RA) will be inhibited.

- Automatic (traffic/resolution advisories)

- The mode S transponder is fully operational. TCAS will operate normally and issue the appropriate interrogations and perform all tracking functions. TCAS will issue traffic advisories (TA) and resolution advisories (RA), when appropriate.

TCAS alerts

| |

| TCAS II typical envelope |

| |||||||||||||

| TCAS II types of RA |

TCAS II issues the following types of aural annunciations:

- Traffic advisory (TA)

- Resolution advisory (RA)

- Clear of conflict

When an RA is issued, pilots are expected to respond immediately to the RA unless doing so would jeopardize the safe operation of the flight. This means that aircraft will at times have to manoeuver contrary to ATC instructions or disregard ATC instructions. In these cases, the controller is no longer responsible for separation of the aircraft involved in the RA until the conflict is terminated.

On the other hand, ATC can potentially interfere with the pilot’s response to RAs. If a conflicting ATC instruction coincides with an RA, the pilot may assume that ATC is fully aware of the situation and is providing the better resolution. But in reality ATC is not aware of the RA until the RA is reported by the pilot. Once the RA is reported by the pilot, ATC is required not to attempt to modify the flight path of the aircraft involved in the encounter. Hence, the pilot is expected to “follow the RA” but in practice this does not yet always happen.

Some States have implemented “RA downlink” which provides air traffic controllers with information about RAs posted in the cockpit obtained via Mode S radars. Currently, there are no ICAO provisions concerning the use of RA downlink by air traffic controllers.

The following points receive emphasis during pilot training:

- Do not manoeuver in a direction opposite to that indicated by the RA because this may result in a collision.

- Inform the controller of the RA as soon as permitted by flight crew workload after responding to the RA. There is no requirement to make this notification prior to initiating the RA response.

- Be alert for the removal of RAs or the weakening of RAs so that deviations from a cleared altitude are minimized.

- If possible, comply with the controller’s clearance, e.g. turn to intercept an airway or localizer, at the same time as responding to an RA.

- When the RA event is completed, promptly return to the previous ATC clearance or instruction or comply with a revised ATC clearance or instruction.

Types of traffic and resolution advisories

Pilot/aircrew interaction during a TCAS event

| Aircrew | Controller | |||||

|---|---|---|---|---|---|---|

| Traffic advisory (TA) | ||||||

| Shall not manoeuver their aircraft in response to traffic advisories (TAs) only | Remains responsible for ATC separation | |||||

| Should prepare for appropriate action if an RA occurs; but as far as practicable, pilots should not request traffic information | If requested by the aircrew, shall give traffic information | |||||

| Resolution advisory (RA) | ||||||

| Shall respond immediately and manoeuver as indicated, unless doing so would jeopardize the safety of the airplane | Shall not attempt to modify the flight path of an aircraft responding to an RA | |||||

| Shall follow the RA even if there is a conflict between the RA and an Air Traffic Control (ATC) instruction to manoeuver | Shall not issue any clearance or instruction to the aircraft involved until the pilot reports returning to the terms of the assigned ATC clearance or instruction | |||||

| Shall never manoeuver in the opposite sense to an RA, nor maintain a vertical rate in the opposite sense to an RA | Shall acknowledge the report by using the phrase "ROGER" | |||||

When deviating from an air traffic control instruction or clearance in response to any RA, shall:

| If requested by the aircrew, shall give traffic information | |||||

| Shall promptly comply with any subsequent RAs issued by TCAS | Ceases to be responsible for providing separation between that aircraft and any other aircraft affected as a direct consequence of the manoeuver induced by the RA | |||||

| Shall limit the alterations of the flight path to the minimum extent necessary to comply with the resolution advisories | ||||||

| Clear of conflict (CC) | ||||||

| Shall promptly return to the terms of the ATC instruction or clearance when the conflict is resolved | Shall resume responsibility for providing separation for all the affected aircraft when he acknowledges:

| |||||

| Shall notify ATC after initiating a return to or resuming the current clearance | ||||||

Safety aspects of TCAS

Safety studies on TCAS estimate that the system improves safety in the airspace by a factor of between 3 and 5.However, it is well understood that part of the remaining risk is that TCAS may induce midair collisions: "In particular, it is dependent on the accuracy of the threat aircraft’s reported altitude and on the expectation that the threat aircraft will not make an abrupt maneuver that defeats the TCAS Resolution Advisory (RA). The safety study also shows that TCAS II will induce some critical near midair collisions..." (See page 7 of Introduction to TCAS II Version 7 and 7.1 (PDF) in external links below).

One potential problem with TCAS II is the possibility that a recommended avoidance maneuver might direct the flight crew to descend toward terrain below a safe altitude. Recent requirements for incorporation of ground proximity mitigate this risk. Ground proximity warning alerts have priority in the cockpit over TCAS alerts.

Some pilots have been unsure how to act when their aircraft was requested to climb whilst flying at their maximum altitude. The accepted procedure is to follow the climb RA as best as possible, temporarily trading speed for height. The climb RA should quickly finish. In the event of a stall warning, the stall warning would take priority.

Both cases have been already addressed by Version 7.0 of TCAS II and are currently handled by a corrective RA together with a visual indication of a green arc in the IVSI display to indicate the safe range for the climb or descent rate. However, it has been found that in some cases these indications could lead to a dangerous situation for the involved aircraft. For example, if a TCAS event occurs when two aircraft are descending one over the other for landing, the aircraft at the lower altitude will first receive a "Descend, descend" RA, and when reaching an extreme low altitude, this will change to a "Adjust Vertical Speed, Adjust" RA, together with a green arc indication directing the pilot to level off the aircraft. This could place the aircraft dangerously into the path of the intruder above, who is descending to land. A change proposal has been issued to correct this problem.

Relationship to automatic dependent surveillance-broadcast (ADS-B)

Automatic dependent surveillance-broadcast (ADS-B) messages are transmitted from aircraft equipped with suitable transponders, containing information such as identity, location, and velocity. The signals are broadcast on the 1090 MHz radio frequency. ADS-B messages are also carried on a Universal Access Transceiver (UAT) in the 978 MHz band.TCAS equipment which is capable of processing ADS-B messages may use this information to enhance the performance of TCAS, using techniques known as "hybrid surveillance". As currently implemented, hybrid surveillance uses reception of ADS-B messages from an aircraft to reduce the rate at which the TCAS equipment interrogates that aircraft. This reduction in interrogations reduces the use of the 1030/1090 MHz radio channel, and will over time extend the operationally useful life of TCAS technology. The ADS-B messages will also allow low cost (for aircraft) technology to provide real time traffic in the cockpit for small aircraft. Currently UAT based traffic uplinks are provided in Alaska and in regions of the East coast of the USA.

Hybrid surveillance does not include the use any of the aircraft flight information in the TCAS conflict detection algorithms; ADS-B is used only to identify aircraft that can safely be interrogated at a lower rate.

In the future, prediction capabilities may be improved by using the state vector information present in ADS-B messages. Also, since ADS-B messages can be received at greater range than TCAS normally operates, aircraft can be acquired earlier by the TCAS tracking algorithms.

The identity information present in ADS-B messages can be used to label other aircraft on the cockpit display (where present), painting a picture similar to what an air traffic controller would see and improving situational awareness.

Drawbacks to TCAS and ADS-B

The major demonstrated problem of the ADS-B protocol integration is this added verbosity of the extra information transmitted, which is considered unnecessary for collision avoidance purposes. The more data transmitted from one aircraft in accordance with the system design, the lesser the number of aircraft that can participate in the system, due to the fixed and limited channel data bandwidth (1 megabit/second with the 26/64 data bits to packet length bit capacity of the Mode S downlink data format packet). For every Mode S message of 64 bits, the overhead demands 8 for clock sync at the receiver and Mode S packet discovery, 6 for type of Mode S packet, 24 for who it came from. Since that leaves only 26 for information, multiple packets must be used to convey a single message. The ADS-B "fix" proposal is to go to a 128 bit packet, which is not an accepted international standard. Either approach increases channel traffic above the level sustainable for environments such as the Los Angeles Basin.Versions of TCAS

Passive

Collision Avoidance systems which rely on transponder replies triggered by ground and airborne systems are considered passive. Ground and airborne interrogators query nearby transponders for mode C altitude information, which can be monitored by third-party systems for traffic information. Passive systems display traffic similar to TCAS, however generally have a range of less than 7 nautical miles (13 km).TCAS I

TCAS I is the first generation of collision avoidance technology. It is cheaper but less capable than the modern TCAS II system, and is mainly intended for general aviation use. TCAS I systems are able to monitor the traffic situation around a plane (to a range of about 40 miles) and offer information on the approximate bearing and altitude of other aircraft. It can also generate collision warnings in the form of a "Traffic Advisory" (TA). The TA warns the pilot that another aircraft is in near vicinity, announcing "Traffic, traffic", but does not offer any suggested remedy; it is up to the pilot to decide what to do, usually with the assistance of Air Traffic Control. When a threat has passed, the system announces "Clear of conflict".TCAS II

| |

| Change proposal CP112E graphical explanation |

| |||||||||

| Change proposal CP115 graphical explanation |

TCAS II is the second and current generation of instrument warning TCAS, used in the majority of commercial aviation aircraft (see table below). It offers all the benefits of TCAS I, but will also offer the pilot direct, vocalized instructions to avoid danger, known as a "Resolution Advisory" (RA). The suggestive action may be "corrective", suggesting the pilot change vertical speed by announcing, "Descend, descend", "Climb, climb" or "Adjust Vertical Speed Adjust" (meaning reduce vertical speed). By contrast a "preventive" RA may be issued which simply warns the pilots not to deviate from their present vertical speed, announcing, "Monitor vertical speed" or "Maintain vertical speed, Maintain". TCAS II systems coordinate their resolution advisories before issuing commands to the pilots, so that if one aircraft is instructed to descend, the other will typically be told to climb — maximising the separation between the two aircraft.

As of 2006, the only implementation that meets the ACAS II standards set by ICAO was Version 7.0 of TCAS II, produced by three avionics manufacturers: Rockwell Collins, Honeywell, and ACSS (Aviation Communication & Surveillance Systems; an L-3 Communications and Thales Avionics company).

After the Überlingen mid-air collision (July 1, 2002), studies have been made to improve TCAS II capabilities. Following extensive Eurocontrol input and pressure, a revised TCAS II Minimum Operational Performance Standards (MOPS) document has been jointly developed by RTCA (Special Committee SC-147) and EUROCAE. As a result, by 2008 the standards for Version 7.1 of TCAS II have been issued and published as RTCA DO-185B (June 2008) and EUROCAE ED-143 (September 2008).

TCAS II Version 7.1 will be able to issue RA reversals in coordinated encounters, in case one of the aircraft doesn't follow the original RA instructions (Change proposal CP112E). Other changes in this version are the replacement of the ambiguous "Adjust Vertical Speed, Adjust" RA with the "Level off, Level off" RA, to prevent improper response by the pilots (Change proposal CP115).; and the improved handling of corrective/preventive annunciation and removal of green arc display when a positive RA weakens solely due to an extreme low or high altitude condition (1000 feet AGL or below, or near the aircraft top ceiling) to prevent incorrect and possibly dangerous guidance to the pilot (Change proposal CP116).

Studies conducted for Eurocontrol, using recently recorded operational data, indicate that currently the probability of a mid-air collision in European airspace is 2.7 x 10−8 which equates to one in every 3 years. When TCAS II Version 7.1 is implemented, that probability will be reduced by a factor of 4.

TCAS III

Originally designated TCAS II Enhanced, TCAS III was envisioned as an expansion of the TCAS II concept to include horizontal resolution advisory capability. TCAS III was the "next generation" of collision avoidance technology which underwent development by aviation companies such as Honeywell. TCAS III incorporated technical upgrades to the TCAS II system, and had the capability to offer traffic advisories and resolve traffic conflicts using horizontal as well as vertical manouevring directives to pilots. For instance, in a head-on situation, one aircraft might be directed, "turn right, climb" while the other would be directed "turn right, descend." This would act to further increase the total separation between aircraft, in both horizontal and vertical aspects. Horizontal directives would be useful in a conflict between two aircraft close to the ground where there may be little if any vertical maneuvering space.TCAS III attempts to use the TCAS directional antenna to assign a bearing to other aircraft, and thus be able to generate a horizontal maneuver (e.g. turn left or right). However, it was judged by the industry to be unfeasible due to limitations in the accuracy of the TCAS directional antennas. The directional antennas were judged not to be accurate enough to generate an accurate horizontal-plane position, and thus an accurate horizontal resolution. By 1995, years of testing and analysis determined that the concept was unworkable using available surveillance technology (due to the inadequacy of horizontal position information), and that horizontal RAs were unlikely to be invoked in most encounter geometries. Hence, all work on TCAS III was suspended and there are no plans for its implementation. The concept has later evolved and been replaced by TCAS IV.

TCAS IV

TCAS IV uses additional information encoded by the target aircraft in the Mode S transponder reply (i.e. target encodes its own position into the transponder signal) to generate a horizontal resolution to an RA. Obviously, this requires the target aircraft to have some data link capability at a minimum. In addition, some reliable source of position (such as Inertial Navigation System or GPS) is needed on the target aircraft in order for it to be encoded.TCAS IV has replaced the TCAS III concept by the mid 1990s. One of the results of TCAS III experience has been that the directional antenna used by the TCAS processor to assign a bearing to a received transponder reply is not accurate enough to generate an accurate horizontal position, and thus a safe horizontal resolution. TCAS IV uses additional position information encoded on an air-to-air data link to generate the bearing information, so the accuracy of the directional antenna would not be a factor.

TCAS IV development continued for some years, but the appearance of new trends in data link such as Automatic Dependent Surveillance - Broadcast (ADS-B) have pointed out a need to re-evaluate whether a data link system dedicated to collision avoidance such as TCAS IV should be incorporated into a more generic system of air-to-air data link for additional applications. As a result of these issues, the TCAS IV concept was abandoned as ADS-B development started.

Current implementation

Although the system occasionally suffers from false alarms, pilots are now under strict instructions to regard all TCAS messages as genuine alerts demanding an immediate, high-priority response. Windshear Detection and GPWS alerts and warnings have higher priority than the TCAS. The FAA and most other countries' authorities' rules state that in the case of a conflict between TCAS RA and air traffic control (ATC) instructions, the TCAS RA always takes precedence (this is mainly because of the TCAS-RA inherently possessing a more current and comprehensive picture of the situation than air traffic controllers, whose radar/transponder updates usually happen at a much slower rate than the TCAS interrogations). If one aircraft follows a TCAS RA and the other follows conflicting ATC instructions, a collision can occur, such as the July 1, 2002 Überlingen disaster. In this mid-air collision, both airplanes were fitted with TCAS II Version 7.0 systems which functioned properly, but one obeyed the TCAS advisory while the other ignored the TCAS and obeyed the controller; both aircraft descended into a fatal collision.This accident could have been prevented if TCAS was able to reverse the original RA for one of the aircraft when it detects that the crew of the other one is not following their original TCAS RA, but conflicting ATC instructions instead. This is one of the features that will be implemented within Version 7.1 of TCAS II.

Implementation of TCAS II Version 7.1 has been originally planned to start between 2009 and 2011 by retrofitting and forward fitting all the TCAS II equipped aircraft, with the goal that by 2014 the version 7.0 will be completely phased out and replaced by version 7.1. The FAA and EASA have already published the TCAS II Version 7.1 Technical Standard Order (TSO-C119c and ETSO-C119c, respectively) effective since 2009, based on the RTCA DO-185B and EUROCAE ED-143 standards. On 25 September 2009 FAA issued Advisory Circular AC 20-151A providing guidance for obtaining airworthiness approval for TCAS II systems, including the new version 7.1. On 5 October 2009 the Association of European Airlines (AEA) published a Position Paper showing the need to mandate TCAS II Version 7.1 on all aircraft as a matter of priority. On 25 March 2010 the European Aviation Safety Agency (EASA) published Notice of Proposed Amendment (NPA) No. 2010-03 pertaining to the introduction of ACAS II software version 7.1. On 14 September 2010 EASA published the Comment Response Document (CRD) to the above mentioned NPA. Separately, a proposal has been made to amend the ICAO standard to require TCAS II Version 7.1 for compliance with ACAS II SARPs.

ICAO has circulated an amendment for formal member state agreement which recommends TCAS II Change 7.1 adoption by 1 January 2014 for forward fit and 1 January 2017 for retrofit. Following the feedback and comments from airline operators, EASA has proposed the following dates for the TCAS II Version 7.1 mandate in European airspace: forward fit (for new aircraft) 1 March 2012, retrofit (for existing aircraft) 1 December 2015. These dates are proposed dates, subject to further regulatory processes, and are not final until the Implementing Rule has been published.

Among the system manufacturers, by February 2010 ACSS certified Change 7.1 for their TCAS 2000 and Legacy TCAS II systems, and is currently offering Change 7.1 upgrade for their customers. By June 2010 Honeywell published a white paper with their proposed solutions for TCAS II Version 7.1. Rockwell Collins currently announces that their TCAS-94, TCAS-4000 and TSS-4100 TCAS II compliant systems are software upgradeable to Change 7.1 when available.

Current TCAS Limitations

- TCAS is limited to supporting only vertical separation advisories, more complex traffic conflict scenarios may however be more easily and efficiently remedied by also making use of lateral resolution maneuvers; this applies in particular to traffic conflicts with marginal terrain clearance, or conflict scenarios that are similarly restricted by vertical constraints (e.g. in busy RVSM airspace)

- ATC can be automatically informed about resolution advisories issued by TCAS only when the aircraft is within an area covered by a Mode S, or an ADS-B monitoring network. In other cases controllers may be unaware of TCAS-based resolution advisories or even issue conflicting instructions (unless ATC is explicitly informed by cockpit crew members about an issued RA during a high-workload situation), which may be a source of confusion for the affected crews while additionally also increasing pilot work load. In May 2009, Luxembourg, Hungary and the Czech Republic show downlinked RAs to controllers.

- In the above context, TCAS lacks automated facilities to enable pilots to easily report and acknowledge reception of a (mandatory) RA to ATC (and intention to comply with it), so that voice radio is currently the only option to do so, which however additionally increases pilot and ATC workload, as well as frequency congestion during critical situations.

- In the same context, situational awareness of ATC depends on exact information about aircraft maneuvering, especially during conflict scenarios that may possibly cause or contribute to new conflicts by deviating from planned routing, so automatically visualizing issued resolution advisories and recalculating the traffic situation within the affected sector would obviously help ATC in updating and maintaining situational awareness even during unplanned, ad hoc routing changes induced by separation conflicts.

- Today's TCAS displays do not provide information about resolution advisories issued to other (conflicting) aircraft, while resolution advisories issued to other aircraft may seem irrelevant to another aircraft, this information would enable and help crews to assess whether other aircraft (conflicting traffic) actually comply with RAs by comparing the actual rate of (altitude) change with the requested rate of change (which could be done automatically and visualized accordingly by modern avionics), thereby providing crucial realtime information for situational awareness during highly critical situations.

- TCAS displays today are often primarily range-based, as such they only show the traffic situation within a configurable range of miles/feet, however under certain circumstances a "time-based" representation (i.e. within the next xx minutes) might be more intuitive.

- Lack of terrain/ground and obstacle awareness (e.g. connection to TAWS, including MSA sector awareness), which might be critical for creating feasible (non-dangerous, in the context of terrain clearance) and useful resolution advisories (i.e. prevent extreme descent instructions if close to terrain), to ensure that TCAS RAs never facilitate CFIT (Controlled Flight into Terrain) scenarios.

- Aircraft performance in general and current performance capabilities in particular (due to active aircraft configuration) are not taken into account during the negotiation and creation of resolution advisories (as it is the case for differences between different types of aircraft, e.g. turboprop/jet vs. helicopters), so that it is theoretically possible that resolution advisories are issued that demand climb or sink rates outside the normal/safe flight envelope of an aircraft during a certain phase of flight (i.e. due to the aircraft's current configuration). Furthermore, as all traffic is being dealt with equally, there's no distinction taking place between different types of aircraft, neglecting the option of exploiting aircraft-specific (performance) information to issue customized and optimized instructions for any given traffic conflict (i.e. by issuing climb instructions to those aircraft that can provide the best climb rates, while issuing descend instructions to aircraft providing comparatively better sink rates, thereby hopefully maximizing altitude change per time unit, that is separation). As an example, TCAS can order an aircraft to climb when it is already at its service ceiling for its current configuration.

- TCAS is primarily extrapolation-oriented, as such it is using algorithms trying to approximate 4D trajectory prediction using the "flight path history", in order to assess and evaluate the current traffic situation within an aircraft's proximity, however the degree of data- reliability and usefulness could be significantly improved by enhancing said information with limited access to relevant flight plan information, as well as to relevant ATC instructions to get a more comprehensive picture of other traffic's (route) plans and intentions, so that flight path predictions would no longer be merely based on estimations but rather actual aircraft routing (FMS flight plan) and ATC instructions. If TCAS is modified to use data that is used by other systems, care will be required to ensure that the risks of common failure modes are sufficiently small.

- TCAS is not fitted to many smaller aircraft mainly due to the high costs involved (between $25,000 and $150,000). Many smaller personal business jets for example, are currently not legally required to have TCAS installed, even though they fly in the same airspace as larger aircraft that are required to have proper TCAS equipment on board. The TCAS system can only perform at its true operational potential once all aircraft in any given airspace have a properly working TCAS unit on board.

External links

- EUROCONTROL ACAS Website

- TCAS II Version 7.1

- Discussion of TCAS

- AIS-P/TailLight alternative to TCAS and ADS-B without the problems of TCAS and ADS-B

- Critical discussion of TCAS using hypothetical abuse/exploit scenarios of TCAS usage

- Introduction to TCAS II Version 7

- Introduction to TCAS II Version 7.1

- Decision criteria for regulatory measures on TCAS II version 7.1

- TCAS User Interface Awareness video toolkit on Skybrary

- Collision avoidance on the UKCS (TCAS II Trial) by Mark Prior (Bristow)

- Private Jet Safety