Flight simulation is an artificial re-creation of aircraft flight and various aspects of the flight environment. This includes the equations that govern how aircraft fly, how they react to applications of their controls and other aircraft systems, and how they react to the external environment such as air density, turbulence, cloud, precipitation, etc. Flight simulation is used for a variety of reasons, including flight training (mainly of pilots), for the design and development of the aircraft itself, and for research into aircraft characteristics, control handling qualities, and so forth.

Flight simulations have varying degrees of hardware, modelling detail and realism that depend on their purpose. They can range from PC laptop-based models of aircraft systems, to simple replica cockpits for familiarisation purposes, to more complex cockpit simulations with some working controls and systems, to highly detailed cockpit replications with all controls and aircraft systems and wide-field outside-world visual systems, all mounted on six degree-of-freedom (DOF) motion platforms which move in response to pilot control movements and external aerodynamic factors.

History of flight simulation

Before World War I

The first known flight simulation device was to help pilots fly the Antoinette monoplane. Whereas the earlier Wright designs used levers for pitch and roll control, the Antoinette used two wheels mounted left and right of the pilot, one for pitch and one for roll. Although the pitch wheel operated in a natural sense, the roll wheel did not (this had to wait until the "invention" of the centrally-mounted control column or "stick" or "joystick").

A training rig was developed in 1909 to help the pilot operate the control wheels before the aircraft was flown. This consisted of a seat mounted in a half-barrel and the two wheels. The whole unit was pivoted so that assistants outside could pitch and roll the device in accordance with the pilot's use of the wheels, using long wooden rods attached to the barrel structure. A full-size model of the "Antoinette Barrel Trainer" is in the foyer of the Airbus Training Centre at Toulouse, France.

World War I (1914-18)

A number of pilot training devices were developed during World War I. Some, like the earlier Antoinette trainer of 1909, were for teaching pilots how to operate the flight controls. Examples include a 1915 UK trainer with a "rocking" cockpit described by H G Anderson, moving cockpit trainers by Lender and Heidelberg in France (patented in 1917), and the U.S."Ruggles Orientator" by W G Ruggles, patented in 1917.

Air Gunnery. Another area of training was for air gunnery by the pilot or a specialist air gunner. Firing at a moving target requires aiming ahead of the target (the so-called lead-angle) to allow for the time of travel of the bullets to reach the vicinity of the target. This is sometimes also called "deflection shooting" and requires skill and practice. During World War I, some ground-based simulators were developed to teach this skill to new pilots.

The 1920s and 1930s

|

| Link Trainer |

The best-known early flight simulation device was the Link Trainer, produced by Edwin Link in Binghamton, New York, USA, which he started building in 1927, later patenting his design which was first available for sale in 1929. The Link Trainer was a basic metal frame flight simulator usually painted in its well known blue color. Some of these early war era flight simulators still exist, but it is becoming increasingly difficult to find working examples.

The Link family firm in Binghamton manufactured keyboard organs, and Edwin Link was therefore familiar with components such as leather bellows, reed switches and so forth. He was also an amateur pilot, but was not satisfied with the amount of real flying training that was available. He decided to build a ground-based device to provide such training without the restrictions of weather and the availability of aircraft and flight instructors. His design had a pneumatic motion platform driven by inflatable bellows which provided pitch and roll cues. An electric motor rotated the platform, providing yaw cues. A generic replica cockpit with working instruments was mounted on the motion platform. When the cockpit was covered over, pilots could practice flight by instruments in a safe environment. The motion platform gave the pilot cues of real angular motion in pitch (nose up and down), roll (wing up or down) and yaw (nose left and right).

Initially, aviation flight schools showed little interest in the "Link Trainer". Link also demonstrated his trainer to the US Army Air Force (USAAF), but with no result. However, the situation changed in 1934 when the Army Air Force was given a Government contract to fly the postal mail. This included having to fly in bad weather as well as good, for which the USAF had not previously carried out much training. During the first weeks of the mail service, nearly a dozen Army pilots were killed. The Army Air Force hierarchy remembered Ed Link and his trainer. Link flew in to meet them at Newark Field in New Jersey, and they were impressed in his ability to arrive on a day with poor visibility, due to practice on his training device. The result was that the USAAF purchased four Link Trainers at $3,500 each, and this can be said to mark the start of the world flight simulation industry.

The company Link Aviation Devices Inc was then formed, and sales followed to others including the UK Royal Air Force and, ironically in view of the Pearl Harbor attack on 7 December 1941, to the Imperial Japanese Naval Air Arm.

World War II (1939-45)

The principal pilot trainer used during World War II was the Link Trainer. Some 10,000 were produced to train new pilots of allied nations, many in the USA and Canada because many pilots were trained in those countries before returning to Europe or the Pacific to fly combat missions.

During World War II, other ground-based flight training devices were produced. For instance, in 1943, a fixed-base aircraft-specific trainer for the British Halifax bomber was produced at the RAF Station at Silloth in the north of England. This consisted of a mock-up of the front fuselage of the Halifax, the pilot's flight controls being simulated through an analogue system that gave artificial resistance ("feel") when the pilot moved the controls. Another name for this device was the "Silloth Trainer".

A different type of World War II trainer was for navigating at night by the stars. The Celestial Navigation Trainer of 1941 was 13.7 m (45 ft) high and capable of accommodating the navigation team of a bomber crew. It enabled sextants to be used for taking "star shots" from a projected display of the night sky.

1945 to the 1960s

In 1948, Curtiss-Wright delivered a trainer for the Boeing 377 Stratocruiser transport aircraft to Pan American. This was the first complete aircraft-specific cockpit trainer owned by an airline. There was no motion or visual system, but the cockpit was closely replicated and the controls functioned and produced responses on the cockpit instruments. The device provided training to flight crews in checks, drills and basic flight procedures.

With the advent of jet airliners such as the UK Comet and US Boeing 707 and DC-8, simulators were produced to train for checks and drills, and to avoid using the aircraft for familiarisation exercises that could be carried out in the simulator. An example was the simulator for the Comet 4 which had a 3-axis motion platform on which the forward section of a Comet fuselage was mounted. This was made by the Redifon company of Aylesbury, UK.

Military simulators

With the "cold war" confrontation between the Soviet-backed Warsaw Pact nations and the Western powers in NATO, many new combat aircraft were produced and many new pilots trained.

Updated versions of the Link Trainer were still in use in several Air Forces into the 1960s and early 1970s, mainly for initial flight training but also for refresher training on flight by instruments.

Particularly for large military aircraft, a new generation of aircraft-specific cockpit trainers were produced using the analogue technology of the time. Many were fixed-base and where they had closely-replicated cockpits and models of aircraft performance and flight dynamics, were Flight Simulators (compared to Cockpit Procedure Trainers, CPTs, that did not have the flight dynamics programmes). In the Flight simulators, complete real-time flight profiles could be practised including faults and emergency drills.

Some of these analogue flight simulators simulated nuclear flash by using a photographic flashbulb outside the cockpit windows. Examples with photo-flash systems included the UK V-bomber simulators for the Valiant, Vulcan and Victor, produced by the Redifon company at Aylesbury and Crawley in the late 1950s and early 1960s. The simulator windows were of "frosted glass" because there was no visual system, although simple "model board" visuals using monochrome imagery were added in the late 1960s to some of these simulators.

Introduction of visual systems

The early visual systems used a small physical terrain model, normally called a "model board". The model board was illuminated, typically by an array of fluorescent light tubes (to avoid shadowing), and a miniature camera was moved over the model terrain in accordance with the pilot's control movements. The resultant image was then displayed to the pilot. Only limited geographical areas could be simulated in this manner, and for civil flight simulators were usually limited to the immediate vicinity of an airport or airports. In military flight simulators, as well as airfields, model boards were produced for larger areas that included terrain for practicing low flying and attacking targets. During the "cold war" between NATO and the Warsaw Pact powers, some model boards with large areas of real terrain were produced before being superseded by digital image generation systems.

Developments in motion systems

The motion system in the 1929 Link Trainer design gave movements in pitch, roll and yaw, but the payload (weight of the replica cockpit) was limited. For flight simulators with heavier cockpits, the Link Division of General Precision Inc. (later part of Singer Corporation and now part of L-3 Communications) in 1954 developed a system where the cockpit was housed within a metal framework that provided 3 degrees of displacement in pitch, roll, and yaw. By 1964, improved versions of this system provided displacements of up to 10 degrees.

It was found that six jacks in the appropriate layout could produce all six degrees of freedom that are possible for a body that can freely move. These are the three angular rotations pitch, roll and yaw, and the three linear movements heave (up and down), sway (side to side) and surge (fore and aft). The design of such a 6-jack (hexapod) platform was used first by Eric Gough in 1954 in the automotive industry and further refined by Stewart in a 1966 paper to the UK Institution of Mechanical Engineers

From about 1977, aircraft simulators for Commercial Air Transport (CAT) aircraft were designed with ancillaries such as the Instructor Operating Station (IOS), computers, etc., being placed on the motion platform along with the replica cockpit, rather than being located off the motion platform.

Computing in flight simulators

The use of digital computers for flight simulation began in the 1960s and became universal by the 1980s. Originally these were from specialist high-end computer manufacturers such as Concurrent, Encore, Harris, IBM, etc., but with the increasing power of the PC, arrays of high-end PCs are now also used as the primary computing medium in flight simulators.

Visual display systems

The early model-board display systems generally used TV screens in front of the replica cockpit to display the Outside World (OTW) visual scene to the crew. Early computer-based Image Generator systems also used TV screens and sometimes projected displays. The focal distance of these displays was the distance of the screen from the crew, whereas objects in the real OTW visual scene are at a more distant focus, those close to the horizon being effectively at infinity.

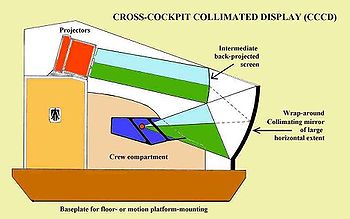

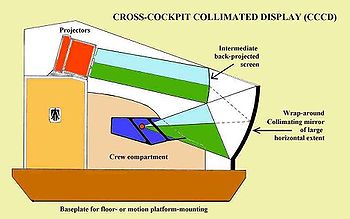

Distant-Focus displays

In 1972, the Singer-Link company, headquartered at Binghamton, New York State, developed a display unit that produced an image at a distant focus. This took the image from a TV screen but displayed it through a collimating lens which had a curved mirror and a beamsplitter device. The focal distance seen by the user was set by the amount of vertical curvature of the mirror. These collimated display systems improved realism and "depth perception" for visual scenes that included distant objects.

Optical infinity This above was achieved by adjusting the focal distance so that it was above what is sometimes referred to as "optical infinity", which is generally taken as about 30 feet or 9 meters. In this context, "Optical Infinity" is the distance at which, for the average adult person, the angle of view of an object at that distance is effectively the same from both the left and right eyes. For objects below this distance, the angle of view is different for each eye, leading to the brain being able to process scenes in a stereoscopic or three-dimensional sense. The inference is that, in simulation display technology, for scenes with objects which in the real world are at distances over about 9 meters / 30 feet, there is little advantage in using two-channel imagery and stereoscopic display systems.

Collimated Monitor Design The 1972 Singer-Link collimated monitors had a horizontal field of view (FoV) of about 28 degrees. In 1976, wider-angle units were introduced with a 35 degree horizontal FoV, and were called 'WAC windows', standing for 'Wide Angle Collimated', and this became a well-used term. Several "WAC Window" units would be installed in a simulator to provide an adequate field of view to the pilot for flight training. Single-pilot trainers would typically have three display units (center, left and right), giving a FoV of about 100 degrees horizontally and between 25 and 30 degrees vertically.

Viewing Volume and user's Eye-point For all of these Collimated Monitor units, the area from which the user had a correct view of the scene (the "Viewing Volume" from the user's "Eye-point") was quite small. This was no problem in single-seat trainers because the monitors could be positioned in the correct position for the pilots average eye-point. However, in multi-crew aircraft with pilots seated side-by-side, this led to each pilot only being able to see the correct outside-world scene through the collimated monitors that were positioned for that pilot's own eye-point. If a pilot looked across the cockpit towards the other pilot's display monitors, this was outside the viewing volume for those monitors and distortions or even "black holes" would be seen because the viewing angle was so far outside the Viewing Volume for the display units concerned. Clearly, for simulators with side-by side crew, a system that gave correct Cross-Cockpit viewing was required.

Cross-Cockpit Viewing

A breakthrough occurred in 1982 when the Rediffusion company of Crawley, UK, introduced their Wide-angle Infinity Display Equipment (WIDE(TM)) system. This used a curved mirror of large horizontal extent to allow distant-focus collimated viewing in a continuous, seamless, horizontal display, by pilots seated side-by-side. The Outside-World (OTW) image was back-projected on a screen above the replica cockpit, and it was the reflection from this screen that was viewed by the pilots. For a diagram of a cross-cockpit display and examples of flight simulators that use it, see the entry under Collimated light. To avoid the weight and fragility of using a large glass mirror, the reflective material was on a flexible mylar sheet. When the simulator is in operation, the flexible sheet is held to an accurate shape by being attached to a shaped former by suction pressure using a small pump. The other major flight simulation companies now produce their own types of mirror-based cross-cockpit displays and these are now utilized in most Full flight simulators of Regulatory Levels C and D. The original Cross-Cockpit display systems used three projectors mounted on top of the replica cockpit and had a Field-of-View (FoV) of 150 degrees horizontally by 30 degrees vertically. With five projectors the horizontal FoV could be extended to 220 degrees. Developments have allowed these figures for three- and five-projector systems to be extended to 180 degrees with three projectors and 240 degrees with five.

Types of flight training devices in service

Training for pilots

|

| Cockpit of a twinjet flight simulator. |

Flight simulation is used extensively in the aviation industry for the training of pilots and other flight crew in both civil and military aircraft. It is also used for the training of maintenance engineers in aircraft systems, and has applications in aircraft design and development, also in aviation and other research.

Several different types of devices are utilized in modern flight training. These range from simple Part-Task Trainers (PTTs) that cover one or more aircraft systems to Full Flight Simulators (FFS) with comprehensive aerodynamic and systems modeling. This spectrum encompasses a wide variety of fidelity in both physical cockpit characteristics and quality of software models, as well as various implementations of sensory cues such as sound, motion, and visual systems. The following training device types are in common use:

- Cockpit Procedures Trainer (CPT) - Used to practice basic cockpit procedures, such as emergency checklists, and for cockpit familiarization. Certain aircraft systems may or may not be simulated. The aerodynamic model is usually extremely generic if one is even present at all. CPTs are usually not regulated.

- Aviation Training Device (ATD) - Used for basic training of flight concepts and procedures. A generic flight model representing a "family" of aircraft is installed, and many common flight systems are simulated.

- Basic Instrument Training Device (BITD) - A basic training device primarily focused on generic instrument flight procedures.

- Flight and Navigation Procedures Trainer (FNPT) - Used for generic flight training. A generic, but comprehensive flight model is required, and many systems and environmental effects must be provided.

- Flight Training Device (FTD) - Used for either generic or aircraft specific flight training. Comprehensive flight, systems, and environmental models are required. High level FTDs require visual systems but not the characteristics of a Full Flight Simulator (FFS), see below.

- Full flight simulator (FFS) - Used for aircraft-specific flight training under rules of the appropriate National Civil Aviation Regulatory Authority. Under these rules, relevant aircraft systems must be fully simulated, and a comprehensive aerodynamic model is required. All FFS require outside-world (OTW) visual systems and a motion platform.

- Full Mission Simulator (FMS) - used by the military to denote a simulator capable of training all aspects of an operational mission in the aircraft concerned.

In many professional flight schools, initial training is conducted partially in the aircraft, and partially in relatively low cost training devices such as FNPTs and FTDs. As the student becomes familiar with basic aircraft handling and flight skills, more emphasis is placed on instrument flying, cockpit resource management (CRM), and advanced aircraft systems, and the portion of flight training conducted in these devices increases significantly. Finally, for more advanced aircraft-specific training, Full Flight Simulators (FFS) are used, particularly as part of conversion to the Commercial Air Transport (CAT) aircraft that the pilot will eventually fly.

For many commercial pilots, most aircraft orientation and recurrent training is conducted in high level FTDs or FFS.

In comparison to training in an actual aircraft, simulation based training allows for the training of maneuvers or situations that may be impractical (or even dangerous) to perform in the aircraft, while keeping the pilot and instructor in a relatively low-risk environment on the ground. For example, electrical system failures, instrument failures, hydraulic system failures, environmental system failures, and even flight control failures can be simulated without risk to the pilots or an aircraft.

Instructors can also provide students with a higher concentration of training tasks in a given period of time than is usually possible in the aircraft. For example, conducting multiple instrument approaches in the actual aircraft may require significant time spent repositioning the aircraft, while in a simulation, as soon as one approach has been completed, the instructor can immediately preposition the simulated aircraft to an ideal (or less than ideal) location from which to begin the next approach.

Flight simulation also provides an economic advantage over training in an actual aircraft. Once fuel, maintenance, and insurance costs are taken into account, the operating costs of an FSTD are usually substantially lower than the operating costs of the simulated aircraft. For some large transport category airplanes, the operating costs may be several times lower for the FSTD than the actual aircraft.

Engineering simulation

Engineering flight simulators are used by aerospace manufacturers for such tasks as:

- Development and testing of flight hardware. Simulation (emulation) and stimulation techniques can be used, the latter being where real hardware is fed artificially-generated or real signals (stimulated) in order to make it work. Such signals can be electrical, RF, sonar, etc., depending on the equipment to be tested.

- Development and testing of flight software. It is much safer to develop critical flight software on simulators or using simulation techniques than it is to develop using actual aircraft in flight.

- Development and testing of aircraft systems. For electrical, hydraulic, and flight control systems, full-size engineering rigs sometimes called 'Iron Birds' are used during the development of the aircraft and its systems.

Entertainment

Screenshot from FlightGear, a free and open source flight simulator

Amateur flight simulation refers to the simulation of various aspects of flight or the flight environment for purposes other than flight training or aircraft development. A large number of free or commercial flight simulators are available:

- FlightGear, a free and open source flight simulator

- X-Plane, also includes a Space Shuttle and Mars flight simulators

- YS Flight Simulation 2000, a freeware flight simulator targeted at low end systems

- Microsoft Flight Simulator Series - its latest installment (Microsoft Flight Simulator X) now includes space as an area to be discovered, with a payware space shuttle available.

Technology

Motion in flight simulators

|

| A Thales flight simulator at a pitch angle |

A Full flight simulator (FFS) duplicates relevant aspects of the aircraft and its environment, including motion. This is typically accomplished by placing a replica cockpit and visual system on a motion platform. A six degree-of-freedom (DOF) motion platform using six jacks is the modern standard, and is required for the so-called Level D flight simulator standard of civil aviation regulatory authorities such as FAA in the USA and EASA in Europe. Since the travel of the motion system is limited, a principle called 'acceleration onset cueing' (which see) is used. This simulates initial accelerations well, and then returns the motion system to a neutral position at a rate below the pilot's sensory threshold in order to prevent the motion system from reaching its limits of travel.

Flight simulator motion platforms used to use hydraulic jacks but electric jacks are now being used. The latter do not need hydraulic motor rooms and other complications of hydraulic systems, and can be designed to give lower latencies (transport delays) compared to hydraulic systems. Level D flight simulators are used at training centers such as those provided by Airbus, FlightSafety International, CAE, Boeing Training and Flight Services (ex-Alteon) and at the training centers of the larger airlines. In the military, motion platforms are commonly used for large multi-engined aircraft and also in helicopters, except where a training device is designed for rapid deployment to another training base or to a combat zone.

Statistically significant assessments of training transfer from simulator to the aircraft are difficult to make, particularly where motion cues are concerned. Large sample sizes of pilot opinion are required and many subjective opinions tend to be aired, particularly by pilots not used to making objective assessments and responding to a structured test schedule. However, it is generally agreed that a motion-based simulation gives the pilot closer fidelity of flight control operation and aircraft responses to control inputs and external forces. This is described as "handling fidelity", which can be assessed by test flight standards such as the numerical Cooper-Harper rating scale for handling qualities. Generally, motion-based aircraft simulation feels like being in an aircraft rather than in a static procedural trainer. In a re-structuring of civil flight training device characteristics and terminology that will take place in about 2012, the Level D Full flight simulator will be re-designated an ICAO Type 7 and will have improved specifications for both motion and visual systems. This is a result of a rationalisation of worldwide civil flight training devices through which 27 previous categories have been reduced to seven.

Qualification and approval

Procedure

In order for a Flight Simulation Training Device (FSTD) to be used for flight crew training or checking, it must be evaluated by the local National Aviation Authority (NAA), such as the Federal Aviation Administration (FAA) in the United States. The training device in question is evaluated against a set of regulatory criteria, and a number of both objective and subjective tests are conducted on the device. The results of each test, along with other significant information about the FSTD and its operator, are recorded in a Qualification Test Guide (QTG).

The result of the initial evaluation of the FSTD, called the Master QTG (MQTG), details the baseline performance of the device as accepted by the qualifying authority. A periodic re-evaluation, called a recurrent qualification, is performed regularly, generally in one year intervals (although the interval can be as low as six months for some FAA evaluations and as high as three years for some European evaluations), and the performance of the device is evaluated against the MQTG. Any significant deviations may result in the suspension or revocation of the device's qualification.

The criteria against which an FSTD is evaluated are defined in one of a number of regulatory and/or advisory documents. In the United States and China, FSTD qualification is regulated in

14 CFR Part 60. In most of Europe, as well as several other parts of the world, the relevant regulations are defined in

JAR-FSTD A and

JAR-FSTD H. The testing requirements vary between the different levels of qualification, but almost all levels require that the FSTD show that it matches the flight characteristics of the aircraft or family of aircraft being simulated.

The main exception to the above process is the evaluation of an ATD by the FAA. Rather than other FSTD, where each device is evaluated on an individual basis, ATDs are evaluated as a model line. When a manufacturer wishes to have a model of ATD approved, a document that contains the specifications of the model line and that proves compliance with the appropriate regulations is submitted to the FAA. If this document, called a Qualification Approval Guide (QAG) is approved, all future devices conforming to the QAG are automatically approved, and individual evaluation is neither required nor available.

Until the publication of Part 60, qualification was called certification, and QTGs were called Approval Test Guides (ATGs). The terms certification and ATG no longer have any regulatory meaning other than for FSTD that remain qualified under FAA AC 120-45 or any other legacy standard.

Flight Simulator "levels" and other categories

The following levels of qualification are currently being granted for both airplane and helicopter FSTD:

US Federal Aviation Administration (FAA)

- Flight Training Devices (FTD)

- FAA FTD Level 4 - Similar to a Cockpit Procedures Trainer (CPT). This level does not require an aerodynamic model, but accurate systems modeling is required. Helicopter only.

- FAA FTD Level 5 - Aerodynamic programming and systems modeling is required, but it may represent a family of aircraft rather than one specific model.

- FAA FTD Level 6 - Aircraft model specific aerodynamic programming, control feel, and physical cockpit are required.

- FAA FTD Level 7 - Model specific. All applicable aerodynamics, flight controls, and systems must be modeled. A vibration system must be supplied, and this is the first level to require a visual system. Helicopter only.

- Full Flight Simulators (FFS)

- FAA FFS Level A - A motion system is required with at least three degrees of freedom. Airplane only.

- FAA FFS Level B - Requires three axis motion and a higher-fidelity aerodynamic model than Level A. The lowest level of helicopter flight simulator.

- FAA FFS Level C - Requires a motion platform with all six degrees of freedom. Also lower transport delay (latency) over levels A & B. The visual system must have an outside-world horizontal field of view of at least 75 degrees to each pilot.

- FAA FFS Level D - The highest level of FFS qualification currently available. Requirements are for Level C with additions. The motion platform must have all six degrees of freedom, and the visual system must have an outside-world horizontal field of view of at least 150 degrees, with a Collimated (distant focus) display. Realistic sounds in the cockpit are required, also a number of special motion and visual effects.

[European Aviation Safety Agency (EASA, ex JAA)

- Flight Navigation and Procedures Trainer (FNTP)

- EASA FNPT Level I

- EASA FNPT Level II

- EASA FNTP Level III

- MCC - Not a true "level" of qualification, but an add-on that allows any level of FNPT to be used for multi crew cooperation training.

- Flight Training Devices (FTD

- EASA FTD Level 1

- EASA FTD Level 2

- EASA FTD Level 3 - Helicopter only.

- Full Flight Simulators (FFS)

- EASA FFS Level A

- EASA FFS Level B

- EASA FFS Level C

- EASA FFS Level D

Credits

The training or checking credits allowed of an FSTD are based on the level of qualification and the operator's training curriculum. For some experienced pilots, Level D FFS may be used for Zero Flight Time (ZFT) conversions from one type of aircraft to another. In ZFT conversions, no aircraft flight time is required, and the pilot first flies the aircraft (under the supervision of a Training Captain) on a revenue flight.

Manufacturers

Full Flight Simulator manufacturers include;

- FlightSafety International (FSI) (United States),

- Frasca International, Inc.

- L-3 Link

- Rockwell Collins

- Opinicus

- CAE Inc.

- Mechtronix Systems (Canada)

- Sim Industries in the Netherlands

- Indra Sistemas in Spain

- Indra Systems (United States)

- Havelsan in Turkey

- AXIS Flight Training Systems in Austria

- Thales Group in France and the UK

- CSTS Dinamika in Russia

- Aerosim

The UK Thales site at Crawley, near London Gatwick airport, is a successor to the ex-Rediffusion simulator factory. Another flight simulator manufacturer is Aerosim located in Burnsville, Minnesota, USA; their focus is making FTDs and VPTs (virtual procedure trainers).

There are currently about 1280 Full Flight Simulators (FFS) in operation worldwide, certificated for pilot training in the Commercial Air Transport (CAT) sector by the relevant National Civil Aviation Regulatory Authorities (NAA, such as the FAA for the USA and EASA for Europe)

, of which about 550 are in the USA, 75 in the UK, 60 in China (PRC), 50 each in Germany and Japan, and 40 in France. Of these, some 450 were made by CAE, mainly in their Montreal factory, about 380 by Thales and its predecessors Rediffusion, (Singer) Link-Miles, and Thomson CSF, and about 280 by Flight Safety International. L-3 Communications operates a facility in Arlington, Texas which manufactures flight simulators for the military; the division (Link Simulation and Training) traces its legacy back to Link's original invention.

|

| The TL39 3-DoF motion simulator with IOS at MAI University |

Flight simulators are also extensively used for research in various aerospace subjects, particularly in flight dynamics and man-machine interaction (MMI). Both regular and purpose-built research simulators are employed. They range from the simplest ones, which resemble video games, to very specific and extremely expensive designs such as LAMARS, installed at Wright-Patterson Air Force Base, Ohio. This was built by Northrop for the Air Force Research Laboratory (AFRL) and features a large scale five degrees of freedom motion system to a unique design and a 360 degree dome-mounted visual system. The most advanced research simulator with sustained G-capability, unlimited attitude control and a reconfigurable cockpit was developed in a joint-venture of TNO and AMST GmbH and is called DESDEMONA.

Instructor operating stations

Most simulators have Instructor Operating Stations (IOS). At the IOS, an instructor can quickly create any normal and abnormal condition in the simulated aircraft or in the simulated external environment. This can range from engine fires, malfunctioning landing gear, electrical faults, storms, downbursts, lightning, oncoming aircraft, slippery runways, navigational system failures and countless other problems which the crew need to be familiar with and act upon.

Many simulators allow the instructor to control the simulator from the cockpit, either from a console behind the pilot's seats, or, in some simulators, from the co-pilot's seat on sorties where a co-pilot is not being trained. Some simulators are equipped with PDA-like devices in which the instructor can fly in the co-pilot seat and control the events of the simulation, while not interfering with the lesson.

Flight simulators are an essential element in individual pilot as well as flight crew training. They save time, money and lives. The cost of operating even an expensive Level D Full Flight Simulator is many times less than if the training was to be on the aircraft itself and a cost ratio of some 1:40 has been reported for Level D simulator training compared to the cost of training in a real Boeing 747 aircraft.

Modern high-end flight simulators

High-end commercial and military flight simulators have large field-of-view (FoV) image generation and display systems of high resolution. All civil Full Flight Simulators (FFS) and many military simulators for large aircraft and helicopters also have motion platforms for cues of real motion. Platform motions complement the visual cues and are particularly important when visual cues are poor such as at night or in reduced visibility or, in cloud, non-existent. The majority of simulators with motion platforms use variants of the six cylinder Stewart platform to generate cues of initial acceleration. These platforms are also known as Hexapods (literally "six feet") and use an operating principle known as Acceleration onset cueing (which see). Motion bases using modern hexapod platforms can provide about +/- 35 degrees of the three rotations pitch, roll and yaw, and about one metre of the three linear movements heave, sway and surge.

The NASA Ames Research Center in "Silicon Valley" south of San Francisco operates the Vertical Motion Simulator. This has a very large-throw motion system with 60 feet (+/- 30 ft) of vertical movement (heave). The heave system supports a horizontal beam on which are mounted rails of length 40 feet, allowing lateral movement of a simulator cab of +/- 20 feet. A conventional 6-degree of freedom hexapod platform is mounted on the 40 ft beam, and an interchangeable cabin is mounted on the hexapod platform. This design permits quick switching of different aircraft cabins. Simulations have ranged from blimps, commercial and military aircraft to the Space Shuttle. In the case of the Space Shuttle, the large Vertical Motion Simulator was used to investigate a longitudinal pilot-induced oscillation (PIO) that occurred on an early Shuttle flight just before landing. After identification of the problem on the VMS, it was used to try different longitudinal control algorithms and recommend the best for use in the Shuttle programme. After this exercise, no similar Shuttle PIO has occurred. The ability to simulate realistic motion cues was considered important in reproducing the PIO and attempts on a non-motion simulator were not successful (a similar pattern exists in simulating the roll-upset accidents to a number of early Boeing 737 aircraft, where a motion-based simulator is needed to replicate the conditions).

AMST Systemtechnik (Austria) and TNO Human Factors (the Netherlands) have developed the Desdemona flight simulation system for the Netherlands-based research organisation TNO. This large scale simulator provides unlimited rotation via a gimballed cockpit. The gimbal sub-system is supported by a framework which adds vertical motion. Furthermore, this framework is mounted on a large rotating platform with an adjustable radius. The Desdemona simulator is designed to provide sustainable g-force simulation with unlimited rotational freedom.

Radio-controlling simulators

A specific field for flight simulation are radio-controlled models - mostly airplanes and helicopters - that are steered from the ground by a transmitter. Here a major part of the learning curve for the pilot is the coordination between finger movement - typically via two joysticks for pitch/yaw and nick/roll - and the model reaction. RC flight simulator software thus uses an input, mostly an USB cable, from the same transmitter that is used for the actual model. With this setup the pilot can learn basic flying procedures without the risk of damaging the model. Current products use photographic textures from real flight fields and mimic the model and weather behaviour with complex physical models.

Advances in modern electronics

Advances in electronics are now starting to bring pitch & roll motion platforms down into the realms of the high end home pilot. A simple combination of COTS (commercial off the shelf) hardware & software now allows home builders to construct simple pitch & roll platforms with some even building hexapod type platforms. These advances are also making it possible to home build controls with Force Feedback which simulates external forces on the control surfaces of the aircraft including hydraulic failures in control systems & the sensation of a landing on the controls. See also Force Feedback Australian flight & helisim builder Rainman Simulators currently has some of these systems in the development stage.